Category: Cognitive technologies

Tech Yupi style: when candy meets innovation

“You can’t buy happiness, but you can buy a cake — and that’s pretty much the same thing”

Meik Wiking, The Little Book of Hygge

Do you remember that feeling — rushing to the store after school, clutching your lunch money saved from skipped meals, just to blow it all on contraband candy your parents would never buy? Not because they were mean. It’s just… you had to know: would that body part really stick together if you ate too many sweets?

Your eyes would dart between the shelves, overwhelmed by the explosion of colors and catchy names. You wanted it all — but the budget was tight, and choices had to be made. These were real problems. None of that adult nonsense like “they’re not paying our salaries again, we’re working for free this month.” Honestly, what’s the point of paying people who spend their money on butter and bread instead of chocolate?

With a few crumpled bills, you could transform your day into a firework of unforgettable flavors. There was Yupi on the shelf — a fizzy powder that turned plain water into a colorful cocktail bursting with orange tang and a hint of sourness. Right in the middle sat Wagon Wheels — soft sponge cakes layered with chocolate and coated in a crisp shell, tasting like caramel with a whisper of nuts or cookies. By the checkout: Dr Pepper, a soda so bold it wrapped your tongue in caramel, spice, and just a touch of fruity tartness. Next to it, Chupa Chups — bright, fruity lollipops that melted slowly and left a trail of sweet nostalgia. And of course, sparkling at eye level was Hubba Bubba — so soft and stretchy, like a strawberry-flavored cloud you could chew forever.

Many of these treats are long gone, replaced by newer, trendier sweets. But anyone who’s tasted them remembers the flavor of “the past.” In this article, we’ll uncover the sweet secrets behind these iconic candies — and explore how old-school candy-making stacks up against modern-day tech.

Call Me Softly by My Name…

What’s the first thing that grabs your attention when you walk into a candy store? Bright packaging — check. A dizzying variety of treats — check. Unusual names — absolutely.

And those names often raise the most questions. Ask someone to pick up a pack of Love is…, and they’ll instantly know you mean the iconic chewing gum with the sweet little comic inserts — not that you’re in need of some emotional support.

Candy names are full of subtle clues and gentle tricks, designed to instantly trigger a craving. The right word can paint a vivid picture of the flavor before the treat ever touches your tongue. Sometimes, though, the name isn’t marketing spin at all — it’s just an honest reflection of the candy’s shape, texture, or some quirky feature.

Our editorial team dug deep into the most popular candy names of the 1980s and ’90s — and now we’re ready to reveal their true meanings.

Revelation #1:

Gums like Love is… and Orbit communicate an emotional message right in their names — an immediate flash of feeling that helps people associate the product with warmth, comfort, or even romance. The name itself becomes a kind of flavor.

Hubba Bubba goes one step further: its name comes from a phrase used by American soldiers during World War II to express approval or excitement — a cheerful “hubba hubba!” turned into bubble gum joy.

Revelation #2:

Chocolate bars often owe their names to major historical moments — events that, one way or another, gave them a reason to exist.

Take Bounty, for example. It shares its name with the ship HMS Bounty, which was sent to transport breadfruit plants from Tahiti to Britain. The sailors, enchanted by the island and its people (and, reportedly, their newfound romances), weren’t thrilled when the captain ordered them back to sea. They mutinied, set the captain adrift, and returned to paradise. That’s why Bounty became a symbol of tropical bliss — a chocolate bar that promises the same kind of pleasure the sailors once tasted on Tahiti.

The story behind Snickers is far more down-to-earth — and oddly touching. The bar was named after the favorite horse of Frank Mars’s son. The beloved horse passed away just months before the chocolate bar was launched, but its name galloped straight into candy history.

Then there are bars like Milky Way and Nuts, whose names are refreshingly literal. Milky Way was named after a milkshake it was meant to resemble, while Nuts owes its fame — and its name — to the whole hazelnuts packed into every bite.

Revelation #3:

Cookies often get their names from the way they look — like Wagon Wheels, the soft, chocolatey biscuits shaped like old wagon wheels. Western films were all the rage when the cookie was invented, but in the end, it was the shape that sealed the name.

Another example: BON STAR, a round cookie stamped with little chocolate stars, named quite literally for what you see — and taste.

Some cookie makers didn’t bother overthinking things. They went straight for the obvious: ingredients, flavor, or intended audience.

Coffee Joy? A coffee-flavored cookie.

Grandma’s Cookies? Sweet treats that feel like they came straight from grandma’s oven.

Choco Pie? A chocolate-covered cake, plain and simple.

And then there’s Pocky — named after the sound it makes when you snap one in half: pokkin! Yes, really.

Revelation #4:

When it comes to candies and lollipops, the naming game turns into a playground. In the mid-20th century, candy names were often packed with symbolism or crafted to spark a specific association.

Take M&M’s: the name comes from the initials of its two founders — Mars and Murrie.

The chewy fruit candy Mamba was named after the deadly black mamba snake. Why? Its texture was bold, slightly tough — as if you were chewing on something wild and dangerous. The name added an exotic, mysterious edge to the brand.

Skittles got its name because the candy pieces resembled the pins used in the old British game of skittles — a kind of bowling.

Tic Tac was named after the unmistakable click-clack sound the tiny candies make inside their plastic box when you shake them.

And as for the iconic Chupa Chups lollipop? That one was named straight to the point. In Spanish, chupar means “to suck.”

Its creator, Enric Bernat, was a true eccentric. He once claimed that people would first suck on the candy, then chew the gum inside — and eventually, they’d even chew on the stick itself. Everyone laughed. “No one’s going to chew the stick,” they said.

So Bernat came up with a brilliant idea: he’d add two tiny holes to the stick. That way, people could look inside and see if there was anything left to chew.

Who’s laughing now?

Can’t Buy It? Print It.

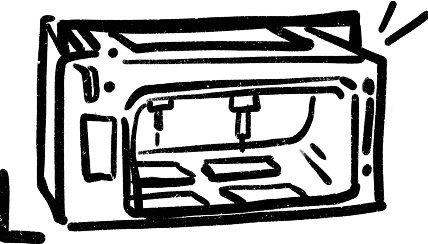

If kids from the ’80s and ’90s found out that one day, you’d be able to print candy the same way you print out a homework assignment, they’d probably faint from pure joy. But today? It barely raises an eyebrow. Technology moves fast — fast enough that we can now 3D print not only sweets, but entire houses you can actually live in.

With food-grade 3D printers, using specialized ingredients and custom software, you can print just about anything edible: candies, chocolate sculptures, cakes, and even pancakes.

Yes — they’re real. Yes — you can eat them. And believe it or not, they taste really good.

Food printers work with special cartridges filled with edible materials — which can be solid, liquid, or powdered. The printer moves its nozzle across the build area, layering material one thin line at a time until a delicious little masterpiece takes shape. Once printed, the sweet treat may be dried, chilled, or even heat-set with laser precision. Some printers use focused beams of light to cook each layer as it’s laid down.

But the real magic? 3D printing allows for mind-blowingly intricate designs — the kind that would be nearly impossible to pull off by hand. Plus, it can tailor every detail to the personal taste of even the pickiest sugar lover.

The world’s first edible 3D printer appeared in the U.S. in 2013. Today, the food industry uses three main types of 3D printers to create next-generation sweets: FDM, PBP, and SLS — each with its own unique role in shaping the future of candy.

FDM (Fused Deposition Modeling) works by layering ingredients one on top of another. Think of it as a high-tech piping bag: the printer extrudes sauces, glazes, dough, or melted chocolate through a precision nozzle, crafting treats in exactly the right shape, size, and thickness.

PBP (Powder Binder Printing) is more like a futuristic version of inkjet printing. A printhead moves across a bed of powder — typically sugar or starch — and selectively sprays a liquid binder (usually water mixed with food additives like thickening or wetting agents). As the binder touches the powder, it fuses the particles together to form the desired shape. Multiple printheads can be used at once to add color variation and increase printing speed.

SLS (Selective Laser Sintering) takes it up a notch. This technique uses high-powered lasers to selectively fuse layers of powder — such as sugar or other dry ingredients — into solid, edible forms. Each laser pass gently melts the particles just enough to bond them together, layer by layer, until a fully-formed, delicious object emerges.

Today, if you crave sweets that once required an entire factory line to produce, all you need is a food-grade 3D printer — and voilà, it’ll do all the pastry work for you in record time.

Case in point: engineers at Columbia University once decided to 3D print a fully layered cake made from seven ingredients — cookie dough, peanut butter, frosting, chocolate spread, strawberry jelly, mashed banana, and cherry syrup.

They crushed the banana with a fork. The cookies were ground up, mixed with water and oil to form a printable paste. The rest of the ingredients? Ready to go straight into the machine.

To get everything flowing smoothly, the food “inks” were chilled for a thicker, more stable consistency, then loaded into plastic cylinders repurposed from medical syringes. These cartridges were slotted into the 3D printer — a machine equipped with both blue and infrared lasers for extra-precise heat treatment.

Their first few tries were a disaster. The cake collapsed under its own weight, layers slid apart, and the whole thing looked more like a sugary landslide than dessert.

But trial by sugar eventually paid off. The team discovered a crucial principle of candy printing: when working with ingredients of different viscosities, the more solid layers need to be printed first. They act as structural supports — or edible “containers” — for the softer, runnier fillings.

In this case, the sturdy cookie-based paste formed the foundation. On top of that came swirls of peanut butter and chocolate spread, followed by banana purée, strawberry jelly, and finally, a drizzle of cherry syrup.

So, if you don’t feel like spending money on store-bought sweets — print them. Just don’t expect it to cost less than a candy bar.

Nano-Gummy: Sweet Tech You Can Eat

There’s one kind of candy most parents don’t mind their kids enjoying in generous amounts: gummy candy. That’s because gummies are often made with natural ingredients, which makes them seem like a healthier alternative to chocolate or hard candy.

Fruit-based gummies, for example, are typically made from fruit or berry purée, combined with sugar, glucose syrup, and gelling agents like pectin, gelatin, or agar-agar. Sugar-free or “diet” gummies use alternative sweeteners and thickening agents. Today’s gummies come in all shapes and sizes — molded or layered, fizzy or glazed, filled or coated, shaped like animals, worms, stars, or tiny bonbons.

Seems simple enough, right? But what if we told you that modern gummy candy can be made using cutting-edge nanotechnology?

In advanced confectionery production, nanoparticles are often added to gummy mixtures to improve texture, flavor, and nutritional value — turning a sweet treat into something surprisingly functional. These nanoparticles — often made from minerals like calcium, magnesium, or zinc, or plant-based antioxidants like quercetin or dihydroquercetin — are added to the gummy syrup either as a powder or as a suspension in a base of sugar, gelatin, and agar.

Once incorporated, the mixture is cooked to the desired consistency, cooled, shaped into fun forms, and packaged for eager hands.

Nanoparticles can alter the texture of the final candy — making it softer, firmer, or delightfully chewy. They also help evenly distribute flavor compounds, extend shelf life, and enrich the candy with essential minerals, vitamins, and health-boosting microelements.

When making gummy candies with nanotechnology, it’s crucial to keep nanoparticle concentrations within safe limits, carefully consider how they might affect the candy’s texture and flavor, and maintain strict quality control — because even the tiniest misstep can seriously damage the final product.

That said, gummy bears remain a true lifesaver for sweet tooths big and small — those who can’t go a day without milk chocolate, sugary candies, and delicious pastries, yet still want to take care of their health. Sound familiar? Then it’s definitely time to make friends with the golden Haribo bears.

People have been creating, inventing, and buying sweets since forever. No matter what kind of day you’re having, a favorite treat can lift your spirits and help you forget your worries — even if only for a moment.

Sweets from the past and present differ in taste, ingredients, and production methods — but they all share one thing: very few people can resist them. As the saying goes, anyone who sits in a room full of candy and doesn’t eat it is a scary person. You do the math.

Your thought is a big bang of ideas. Our journal is its source.

Thank you!